Products

PTFE coated super fiberglass cloth

Product Description

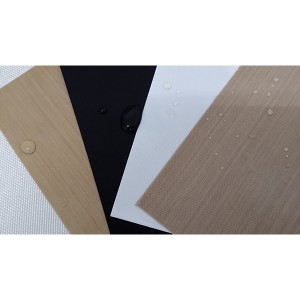

PTFE COATED ARAMID FIBER(SUPER FIBERGLASS) CLOTH

PTFE coated super fiberglass cloth use some special glass fibers, through a special process, which coated fluorine resin. So it has higher strength and tearing resistance. Used on lines where smaller diameter rollers are typical or in applications where steam may be present, the superior mechanical strength of these products allows them to be used successfully in the harshest of environments.

PTFE coating provide more flexibility and improve tear resistance. These fabrics are typically used in applications requiring high-flex properties or belting applications with small diameter pulleys.

Specially formulated PTFE coating provide more flexibility and improve tear resistance. These fabrics are typically used in applications requiring high-flex properties or belting applications with small diameter pulleys.

Anti-static products are made with a specially formulated black PTFE coating. These fabrics eliminates static electricity during operation. Conductive black products are widely used in the apparel industry as conveyor belts in fusing press machines.

Excellent for use in exceptionally tough mechanical applications. Superior characteristics of PTFE & aramid fiber(super fiberglass) products result in increased productivity, longer life time and lower operating costs. Applications may include: freezing of food products, pressing plywood and chipboard, conveyor belting for industrial processing.

| Series | Code | Color | Thickness | Weight | Width | Strength |

| Aramid | AC13 | Original | 0.13mm | 170 g/㎡ | 1200 | 3000/2300N/5cm |

| AC15 | 0.15mm | 220 g/㎡ | 1200 | 4100/3400N/5cm | ||

| AC30 | 0.30mm | 440 g/㎡ | 1200 | 8000/6000N/5cm | ||

| AC35 | 0.35mm | 575 g/㎡ | 1200 | 8500/6500N/5cm | ||

| Super Fiberglass | FC13S | Original | 0.13mm | 200 g/㎡ | 1200 | 1500/1100N/5cm |

| FC23S | 0.23mm | 410 g/㎡ | 1200 | 2400/2100N/5cm |